Manufacturing

Manufacturing facilities must sort and combine raw components to construct and deliver a finished product. The structure of manufacturing systems requires high standards for product and quality control, organized inventory management and efficient use of labor hours. Since manufacturing centers rely more on fixed product lines and more skilled labor operations, facilities should focus on maximizing efficiency rather than flexibility. As with all areas of material handling, the strategic use of automation provides one of the best solutions in the manufacturing sector.

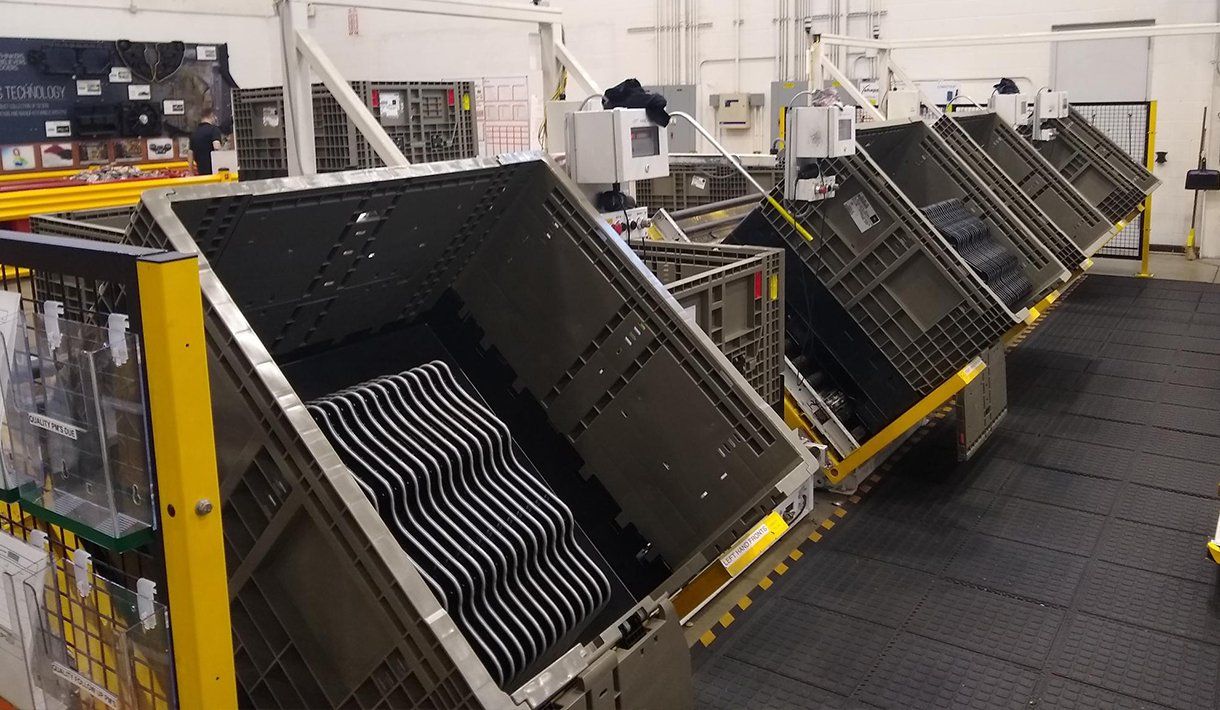

Case Study: Transmission Plant— Indiana

Systems In Motion (SIM) was hired by a large automobile manufacturer with a transmission plant located in Indiana where they created the concept, design and wire a modification to one of the part delivery systems in the plant. This project added power and free rail to the station’s existing trolley system. SIM’s modified system provided a new secondary rail and trolleys with load bars to convey the existing baskets and used pneumatic circuits to assist in material flow at designated stops. This innovative system improved the speed of the automotive plant’s assembly line and the efficiency of operations. We installed 4 high speed, automotive grade VDLs (Vertical Drop Lifters).